EagleBurgmann international

EagleBurgmann WORLDWIDE

With around 250 locations and 90 serve centers, we are represented in the most important economic regions of the world. The advantages are clear: short paths to our customers, fast response times and a shared language.

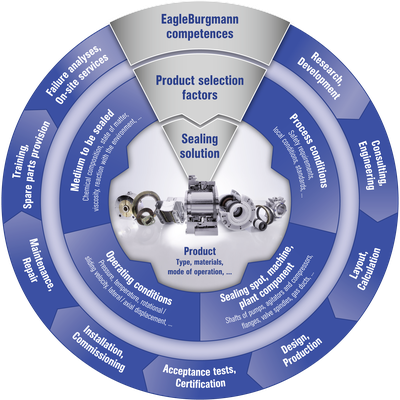

Optimally designing mechanical seals

Several factors play a role in the selection of a mechanical seal, the mechanical seal type, the materials used, and the manner in which a mechanical seal will be operated: process conditions, sealing point where the mechanical seal will be used, operating conditions, and the medium to be sealed. Every system will only work as well as its individual components. If one mechanical seal functions smoothly, then it will lead a largely uneventful life. But as soon as the leakage rate rises or if the mechanical seal even fails, its importance quickly becomes self-evident. Mechanical seals are therefore very important in terms of process stability, plant safety, and economic viability.

Important factors and competencies for the selection of mechanical seals

Elements of a mechanical seal

The mechanical seal essentially consists of two flat, annular sliding surfaces that are pressed together. One sliding surface is fixed to the stationary machine casing, while the other sliding surface is fixed to the rotating shaft. The medium to be sealed, which is generally in contact with the outer edge of the sliding surfaces, penetrates the gap between the sliding surfaces, forming a lubricating film, and emerges at the inner edge as leakage. The pressure differential to be sealed is established in the radial direction. In its simplest form, a mechanical seal can be imagined as a collar that is arranged on, and rotates with, the shaft.

Definition of mechanical seal (abbreviated GLRD)

A mechanical seal is a machine element made to seal the passage point of a rotating part (usually a shaft) through a wall (usually the machine casing). Features of the mechanical seal are two surfaces sliding on each other – usually arranged at right angles to the rotational axle – which are pressed together by axial forces. Between the sliding surfaces is a liquid or gaseous lubricating film.

Every mechanical seal possesses five basic elements:

- One ring (usually the seal face) circulating synchronously with the rotating part (shaft)

- Secondary seal (usually O-ring) between shaft and ring

- A stationary ring (usually the stationary seat) arranged in the stationary part (casing)

- Secondary seal (usually O-ring) between these parts

- Spring for the seal face

Independent of the direction of rotation mechanical seal EagleBurgmann M7N for pressures up to 25 bar, temperatures from -50°C to +220°C and sliding velocities of up to 20 m/S (vg).

Mechanical seal EagleBurgmann M7N, as frequently used in applications of the process industry, in the sector of water applications, or as used in the food industry.

1. Seal face

2. Secondary seal

3. Stationary seat

4. O-ring

5. Spring

The Eagleburgmann Group

Sealing technology for plants and machines

EagleBurgmann is one of the worldwide leading providers of industrial sealing technology. Mechanical seals, seal supply systems, magnetic couplings, carbon floating ring seals, expansion joints, gaskets and packings as well as comprehensive services are used wherever reliability and safety are needed.

Mechanical seals and more

Sealing technology by EagleBurgmann is used worldwide in oil and gas industries, refineries, the petrochemical, chemical, and pharmaceutical industries, food processing, energy, water, mining, paper, aerospace, and other industries. Close to 5,800 employees provide their ideas, solutions, and commitment so that customers can rely on our sealing technology.

What makes us stand out is our excellent quality, great innovative capacity, and an extensive product portfolio for nearly all industrial processes and fields of application. Our product portfolio includes everything from mechanical seals and seal supply systems to magnetic couplings, carbon floating ring seals, expansion joints, and gaskets and packings as well as comprehensive services. Since we are part of the German Freudenberg and Japanese EKK group, we have all the necessary resources for a firmly based reliable partnership.