Espey WKA1200

Espey WKA1200

| Item | Description |

| 1 | Seal ring |

| 2 | Seal ring |

| 3 | Chamber |

| 4 | Lantern |

| 5 | Barriers gas chamber |

| 6 | Chamber |

| 7 | End ring |

| 8 | Pressure ring |

| 9 | O-Ring |

| 10 | Housing |

| 11 | Housing |

| 12 | Lid |

Espey WKA1200

Features

The proven carbon floating ring seal - Optimized to meet the highest standards

- Available as modular Cartridge-Seal

- Flexible layout due to operating parameters

- Weight optimized

- Minimal vibrating mass

- High operational realiability

Advantages

- Plug & Run

- Long-term operation time

- More compact design for tight installation spaces

- Durable ring design with a robust anti-rotation device

- Contactless, low-wear technology ensures maximum operational reliability

Materials

Seal ring: Carbon with titanium bandage

Chamber and housing parts: 1.4021, 1.4571, Hastelloy®, Titan, Inconel®, others

Secondardy seal (elastomer): Fluorocarbon rubber (Viton®), Perfluorocarbon rubber (FFKM), special PTFE seals on request

Secondary seal (flat gasket): Statotherm®-HT/HD, Burasil

Chamber and housing parts: 1.4021, 1.4571, Hastelloy®, Titan, Inconel®, others

Secondardy seal (elastomer): Fluorocarbon rubber (Viton®), Perfluorocarbon rubber (FFKM), special PTFE seals on request

Secondary seal (flat gasket): Statotherm®-HT/HD, Burasil

Standards and approvals

- FDA

Recommended applications

- Integral-gear compressors (one or multi-stage)

- Turboexpanders

- Turbines

- CCUS

- LNG

- Hydrogen

- Energy-storage

- Oil and gas industry

- Refining technology

- Chemical industry

- Petrochemical industry

- Pulp- and paper industry

- Metal production and processing

- Power plant technology

- Gases

Notes

Notes:

General technical features of carbon floating ring seals – compact, efficient, and reliable

Our carbon floating ring seals offer a high-performance solution for demanding sealing requirements in machines and systems. The most important advantages at a glance:

- Compact design: Short axial and radial dimensions – ideal for use in small installation spaces.

- Minimal leakage: The very small operating gap ensures extremely low leakage and increases efficiency.

- Dry running: No need for additional lubrication – low maintenance and reliable operation.

- Adaptable: The sealing rings follow radial shaft deflections and ensure reliable sealing even under dynamic operating conditions.

- Contact-free running: The sealing rings run without contact, which means there is no additional friction – this saves energy and protects the machine.

Product variants

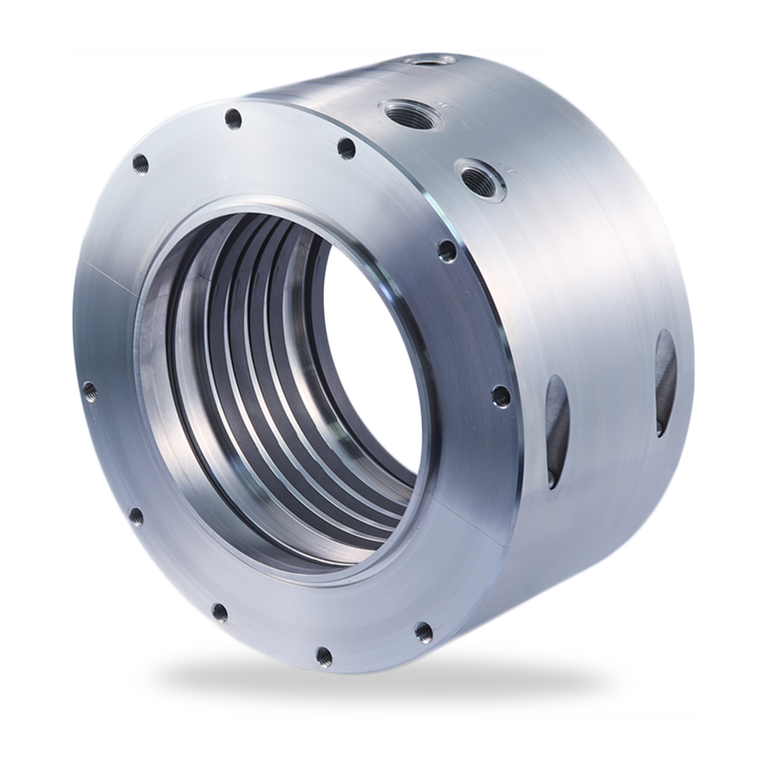

WKA1200: The Espey standard version

- The modular chamber design allows for even more customer-specific adaptations

- More compact design for tight installation spaces

- Durable ring design with a robust anti-rotation device

- Bilateral relief of the sealing ring in the chamber for short-term backpressure operation

- Axially spring-loaded sealing ring – no contact with the shaft due to its own weight

- Contactless, low-wear technology ensures maximum operational reliability

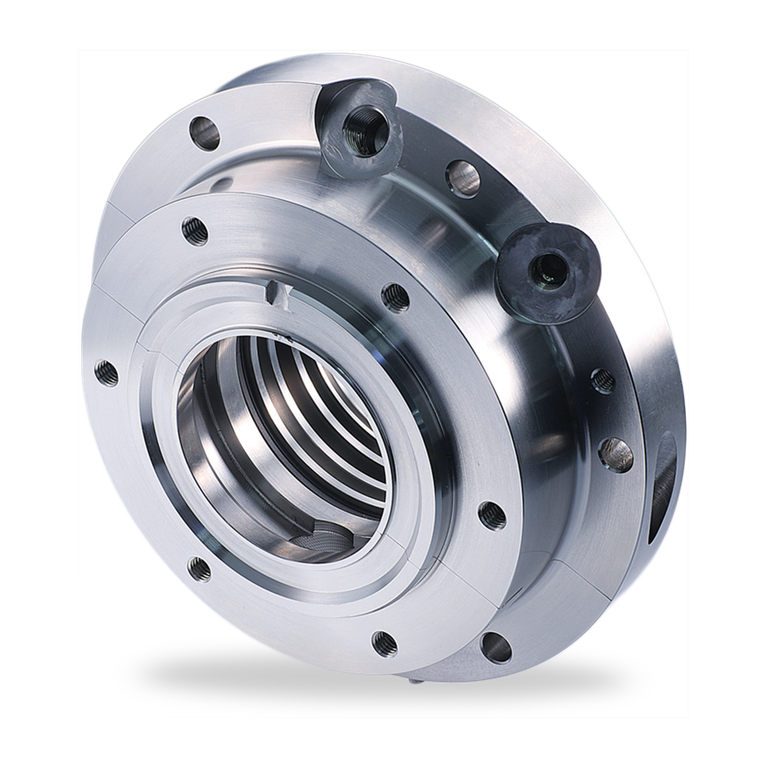

WKA1200-Cartridge: Plug & Run

In addition to our standard version, our Cartridge variant offers the following advantages:

- First to combine: the shaft sleeve, seal, and housing components

- Fully balanced, ready-to-install unit

- Improved handling thanks to integrated components

- Simplified installation

- Easier maintenance

- Minimizes the risk of component damage

- Coal-Floating-Ring- Service-Concept:

Simply select the scope you need

- Available in WKA1200 standard dimensions and also customizable

Similar products

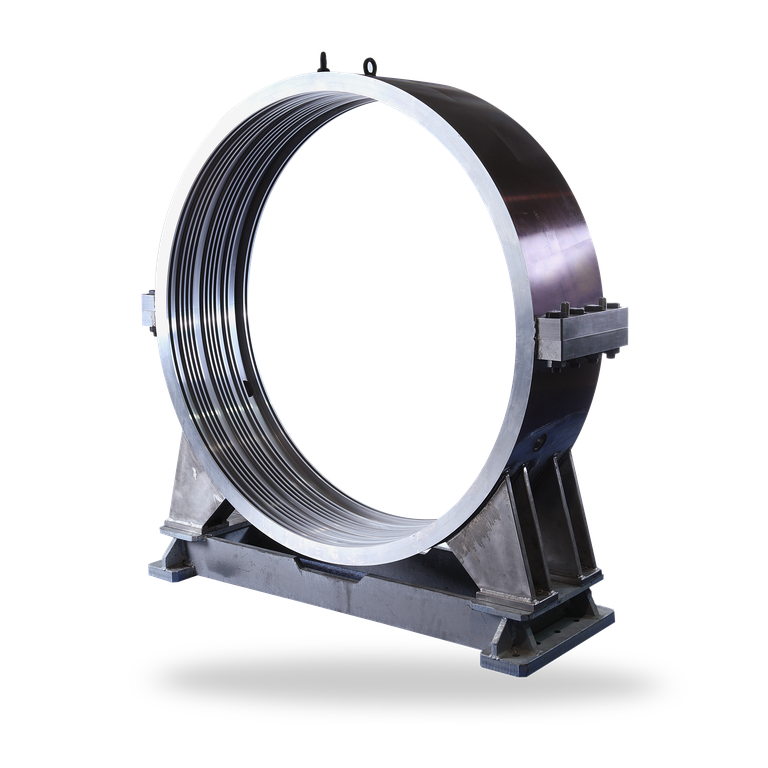

Espey Magna500+ the large seal for diameters from 500 mm

- Split housing design

- Segmented and self-adjusting seal rings

- Virtually maintenance- and wearfree

- Dry-running

- Suitable for horizontal and vertical use

Espey WD200

- Split housing design

- Multi-part seal rings, radially cut

- Very small operation gap - low leakage

- Dry running

- Self-adjusting seal rings

- Seal rings bear radial shaft movements

- Compensates axial shaft movements

- No sealing components mounted on the shaft and hence no additional shaft vibrations

- Seal rings running contact-free - sliding faces and machine consume no additional power

Espey WD200/500

- Multi-part seal rings, radially cut on process side, overlapped mortised with gas tight joints on atmosphere side (adjusting)

- Split housing design

- Lowest possible operation gap - lowest leakage

- Dry running

- Self-adjusting seal rings

- Seal rings bear radial shaft movements

- Compensates axial shaft movements

- Short axial installation length

- No sealing components mounted on the shaft and hence no additional shaft vibrations