MDGS

MDGS

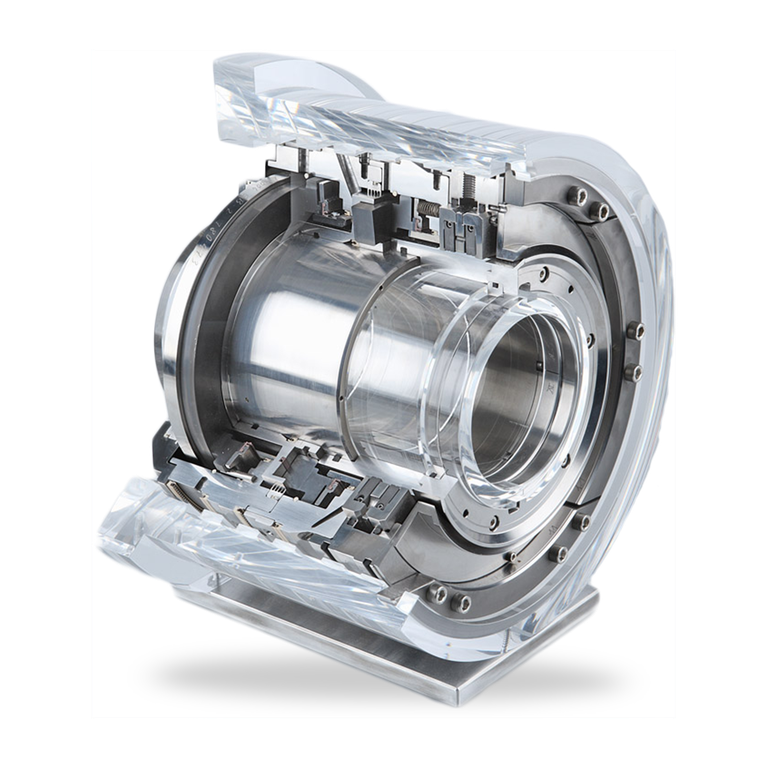

MDGS Tandem seal with intermediate labyrith

Product links separation seals:

EagleBurgmann CSE

EagleBurgmann CSR

EagleBurgmann CobaSeal

| A | Primary seal gas supply |

| B | Primary vent |

| C | Secondary gas seal supply |

| S | Secondary vent |

| D | Separation gas supply |

| Item | Description |

| 1 | Seal face, stationary |

| 2 | Seat, rotating |

| 3 | Thrust ring |

| 4 | Spring |

| 5 | Adapter |

| 6 | Shaft sleeve, intermediate sleeve |

| 7, 8 | Housing (size matched to installation space) |

| 9 | Carbon ring separation seal (CSE) |

| 10 | Intermediate labyrinth |

Product links separation seals:

EagleBurgmann CSE

EagleBurgmann CSR

EagleBurgmann CobaSeal

MDGS

Features

- Gas-lubricated

- Bi-directional

- Compact, radial design

- Ready-to-fit cartridge unit, also available as a component seal

- Single, double, tandem seal and tandem with intermediate labyrinth available

Advantages

- Wear-free and contact-free operation

- Self-cleaning 3D gas grooves

- High gas film stiffness

- Fits into small spaces (e.g. process gas screw compressors)

- Available in various materials for optimized chemical resistance

- Proven, reliable and economical solution

Materials

Seal face: Carbon graphite

Seat: Ductile stainless steel with DM-TiN coating

Secondary seals: FKM

Metal parts: 1.4006 or other stainless steels.

Seat: Ductile stainless steel with DM-TiN coating

Secondary seals: FKM

Metal parts: 1.4006 or other stainless steels.

Standards and approvals

- NACE

- API 692

- Compliant to TA Luft (German Clean Air Act) (double seal, tandem seal)

Recommended applications

- Oil and gas industry

- Refining technology

- Petrochemical industry

- Hydrocarbon gas

- Nitrogen

- Air

- Centrifugal compressors

- Dry process gas screw compressors

- Blowers

Notes

EagleBurgmann MDGS are rugged seals for screw compressors. They have a rotating ring made from ductile

material with a high-performance coating. Rotating rings are “in-situ shrouded”, making them practically

indestructible. The coating offers excellent wear resistance in the low speed range (e.g. coast-down operation) in

which contact between the seal faces is unavoidable.

The stationary, spring-mounted system is optionally available as a sub-cartridge in combination with a rotating seat made from ductile material. A secondary sealing function using O-rings allows it to be applied as a component seal.

Dimensions on request.

The stationary, spring-mounted system is optionally available as a sub-cartridge in combination with a rotating seat made from ductile material. A secondary sealing function using O-rings allows it to be applied as a component seal.

Dimensions on request.

Similar products

CobaDGS - Zero Emission Solution

The sealing solution for reduction of methane-/ process gas emissions

- Gas-lubricated

- Bi-directional

- Ready-to-fit cartridge unit

- Available for following seal arrangements: single and tandem

- Co-axial primary seal

- Separation seals as CobaSeal, carbon rings or labyrinths optional

DGS

- Gas-lubricated

- Uni-directional or bi-directional

- Ready-to-fit cartridge unit

- Single, double, tandem and tandem with intermediate labyrinth available

- Separation seals as labyrinths, carbon rings or CobaSeal are optionally available

PDGS

- Gas-lubricated

- Uni-directional or bi-directional

- Elastomer-free

- Ready-to-fit cartridge unit

- Single, double, tandem seal and tandem with intermediate labyrinth available

- Separation seals as labyrinths, carbon rings or CobaSeal are optionally available